Fighting for animal liberation and an end to speciesism

-

Labeling Machine

- Female

- Vista, CA

- United States

- Blog Posts

- Discussions

- Events

- Groups

- Photos

- Photo Albums

- Videos

RSS

Why Cap Consistency Matters: The Role of Torque Control in Capping Machines

When it comes to packaging, small details make a big difference. A perfectly filled bottle can still fail to convince people to take it off the shelf if the cap isn’t applied correctly. Whether it’s too tight, too loose, or crooked, inconsistent capping can lead to leaks, contamination, product loss, and unhappy customers.

That’s why torque control—the ability of a capper to apply consistent and precise force when tightening caps—is one of the most critical elements in modern packaging operations.

At Accutek Packaging Equipment, we design capping machines that combine speed, accuracy, and torque precision to ensure that every cap is sealed to perfection—no matter the product or container type.

The Importance of Consistent Capping

Capping might seem like a simple process, but it’s one of the most crucial steps in any packaging line. The purpose of a cap goes beyond appearance—it’s a product’s first line of defense against leaks, tampering, and spoilage. And it helps maintain the product’s freshness, potency, and/or carbonation.

When caps are applied inconsistently, you may have to deal with a whole host of problems:

- Loose caps can cause leaks or exposure to air, shortening shelf life.

- Over-tightened caps can crack or deform containers, especially plastic bottles.

- Uneven caps can compromise your brand’s image and lead to product returns.

That’s why consistency is key. A capping machine equipped with proper torque control ensures every cap meets exact specifications—tight enough to protect the product, but not so tight that it damages packaging.

How Torque Control Works in Capping Machines

Torque control refers to the precise measurement and regulation of the twisting force used to secure a cap onto a container. In manual operations, this force varies depending on the operator. But in automated or semi-automated capping machines, torque is controlled mechanically or electronically for perfect repeatability.

Here’s how it works:

- Mechanical Clutches: Many spindle and chuck cappers use mechanical clutches that can be adjusted to apply a consistent level of torque. This prevents over-tightening and ensures every cap is applied uniformly.

- Servo-Driven Torque Systems: In more advanced machines, servo motors measure and electronically control torque. This enables precise torque settings that can be adjusted and monitored through touchscreen interfaces.

- Feedback Sensors: Some systems include torque feedback sensors that detect and record each capping event, allowing operators to track performance and spot irregularities early.

These technologies combine to deliver caps that are applied with precision, ensuring both …

The post appeared first on Accutek Packaging Machine & Equipment.

Automating the Capping Process: When Is the Right Time to Upgrade?

In any production environment, efficiency and consistency are the cornerstones of success. As demand grows and production lines scale up, manual packaging processes often struggle to keep pace. One of the first bottlenecks manufacturers encounter is at the capping stage—a critical step that ensures product safety, shelf life, and presentation quality.

For many businesses, investing in an automated capping machine is the key to unlocking faster throughput, fewer errors, and a more reliable packaging process. But when exactly is the right time to make the switch from manual or semi-automatic capping to full automation?

At Accutek Packaging Equipment, we help companies identify that perfect moment—and design the right packaging machine solution to match.

Why Automate the Capping Process?

Capping might appear straightforward, but it’s one of the most precise and repetitive tasks on a production line. Every cap must be applied with consistent torque, tightness, and alignment to protect the product and maintain brand quality.

Manual capping is feasible for small operations, but as production scales upward, inconsistencies may start to show up. Workers tire over time, torque levels vary, and production speed can’t match growing demand.

Automated capping machines solve these problems by applying consistent force, maintaining accuracy at high speeds, and ensuring uniform quality across every container.

Signs It’s Time to Upgrade to an Automated Capping Machine

If you’re wondering whether your business is ready to take the next step toward automation, here are some clear indicators that it might be time to upgrade your capping process:

- Rising Production Volume

If your team is struggling to keep up with growing orders, automation can provide the boost you need. Automated capping machines maintain a consistent pace that manual labor simply can’t match. - Inconsistent Product Quality

Uneven or improperly sealed caps can lead to leaks, product waste, or damaged packaging. Automated torque control ensures each cap is applied precisely, protecting your product’s integrity and brand reputation. - Increased Labor Costs or Turnover

Manual capping can be physically demanding, leading to fatigue and repetitive strain injuries. Automating the process reduces labor requirements and improves employee safety while freeing up staff for higher-value tasks. - Frequent Rework or Line Downtime

If your operators are constantly stopping the line to fix misapplied caps, automation can eliminate those interruptions and improve overall line efficiency. - Expanding Product Lines

If you’re introducing new products with different cap types or container sizes, a modern capping machine with quick-change components

…

The post appeared first on Accutek Packaging Machine & Equipment.

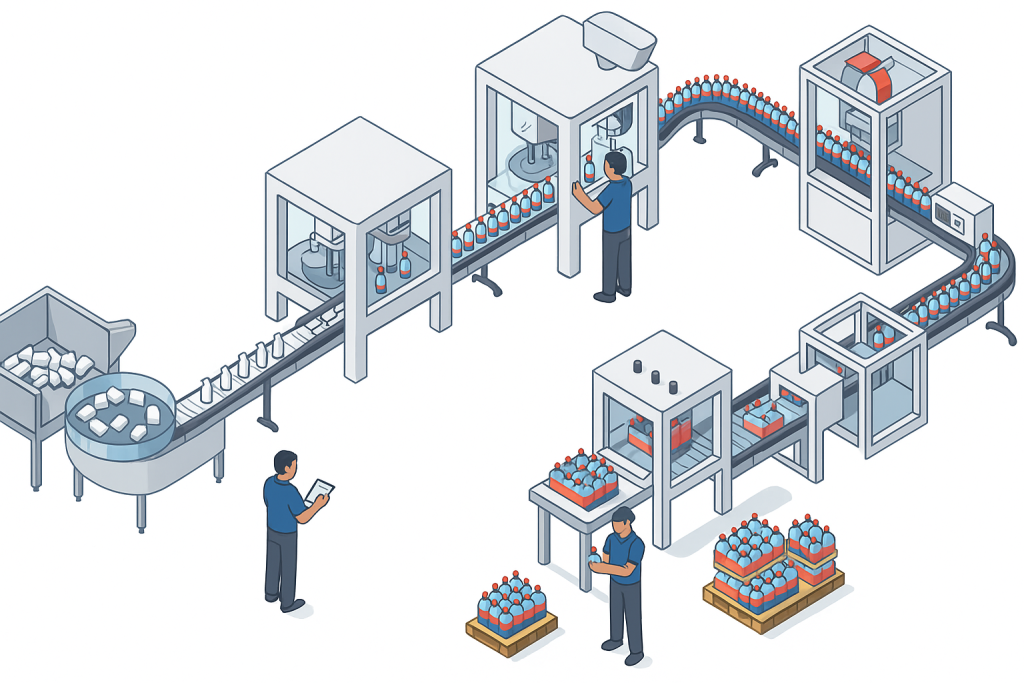

From Filling to Capping: How Integrated Packaging Machines Streamline Production

Are you a manufacturer looking for ways to boost output, cut down on waste, and maintain consistent product quality?

One of the most effective ways to achieve these goals is through integrated packaging machines—systems that combine multiple packaging processes, such as filling and capping, into a single streamlined operation.

At Accutek Packaging Machine & Equipment, we specialize in helping companies like yours optimize their production lines with complete packaging solutions. From precision filling machines to reliable capping machines, our integrated systems are designed to work together seamlessly—boosting productivity while maintaining the highest quality standards.

The Role of Filling Machines in Modern Production

Efficient packaging machine lines usually include a filler. Whether you’re handling liquids, creams, pastes, or powders, the filling machine helps dispense your product into containers with accuracy and consistency.

Modern liquid filling machines use sensors and precision nozzles to ensure exact fill levels, cutting down on waste and boosting production. This is essential because In industries like food and beverage, pharmaceuticals, and cosmetics, even slight inconsistencies can lead to costly product recalls or dissatisfied customers.

Completing the Process with Capping Machines

Once the product is filled, it must be sealed securely—and that’s where cappers come in. Capping is a crucial step that protects product integrity, prevents leaks, and enhances shelf appeal.

A dependable capping machine ensures each cap is applied with the correct torque and alignment, maintaining a professional finish while preserving freshness and safety.

At Accutek, we offer several types of capping equipment, including spindle cappers, chuck cappers, and snap cappers, each suited for specific cap and container types.

When integrated with a filler, conveyor, and labeler, a capping machine completes the automation cycle. This integration enables transitions between each stage, minimizing downtime and manual handling.

Why Integrated Packaging Machines Are the Future

Integrating filling and capping machines into one cohesive system offers several benefits that standalone machines simply can’t match.

- Improved Efficiency – When machines can work together, product transfer is faster and smoother, reducing bottlenecks and increasing production.

- Consistent Quality – Automation reduces human error, so every container is filled and sealed to exacting standards.

- Reduced Labor Costs – You don’t need as many operators to manage multiple systems, allowing your staff to focus on other tasks.

- Smaller Footprint – Integrated systems usually occupy less space on the floor.

- Easier Maintenance – Working with a single manufacturer like Accutek simplifies maintenance, training, and

…

The post appeared first on Accutek Packaging Machine & Equipment.

Gifts Received

Labeling Machine has not received any gifts yet

Labeling Machine's Page

Profile Information

© 2025 Created by Animal Rights Zone.

Powered by

![]()

Comment Wall

You need to be a member of Animal Rights Zone to add comments!

Join Animal Rights Zone